Spark your ingenuity at AVEVA World Partner & Product Expo

Connect with your industrial community and colleagues at the AVEVA World Partner & Product Expo. Engage with experts, deepen your technical...

5 min read

![]() The InCentrik Team

Feb 6, 2024 5:08:48 PM

The InCentrik Team

Feb 6, 2024 5:08:48 PM

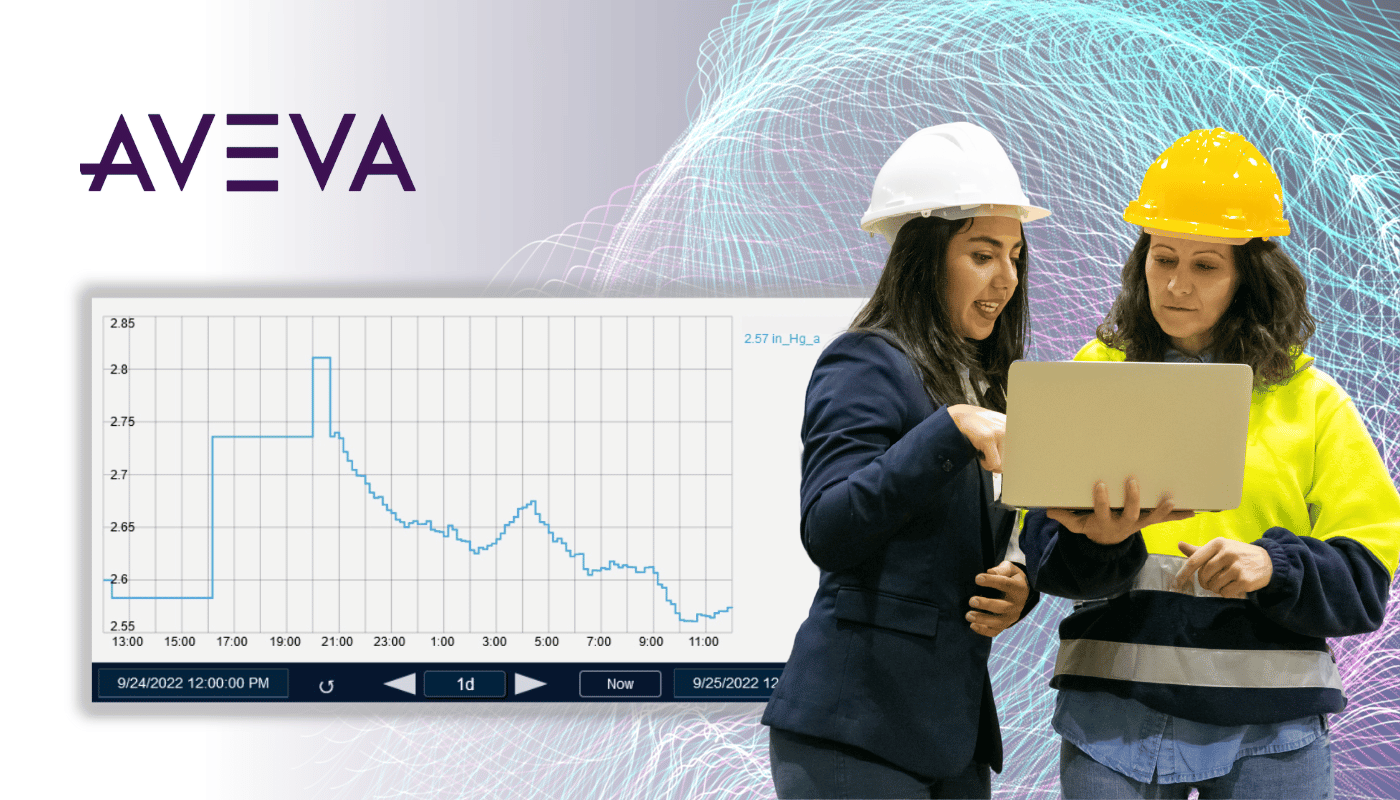

In the realm of industrial automation and data management, AVEVA's PI System (formerly OSIsoft's PI System) stands out as a pivotal technology. As businesses evolve in the digital age, the need for real-time, data-driven decision-making has become paramount. The PI System, a cornerstone in this transformation, is adept at handling the complexities of industrial data.

This blog post explores six top use cases of the AVEVA PI System, illustrating its versatility and impact across various sectors.

Empowering industries with real-time insights and control over their operations.

The backbone of industrial automation is real-time data collection. The PI System excels in gathering data from a myriad of sensors and equipment, providing a comprehensive view of industrial processes. This seamless data acquisition is critical for monitoring operational performance and ensuring optimal control of manufacturing processes.

A standout feature of the PI System is its ability to visualize process performance. This visualization aids in comprehending complex data streams, allowing for a more intuitive understanding of the processes at play. It serves as a vital tool in identifying inefficiencies, enabling operators to make informed decisions to optimize operations.

The real-time data and visualization capabilities of the PI System are instrumental in streamlining industrial operations. By identifying bottlenecks and inefficiencies, companies can implement targeted improvements, leading to enhanced productivity and reduced operational costs.

Maximizing asset performance and longevity through proactive monitoring and maintenance.

The health and performance of critical assets are of utmost importance in industrial settings. The PI System's monitoring capabilities ensure that these assets operate within their optimal parameters, reducing the likelihood of unexpected failures.

One of the key strengths of the PI System is its ability in predictive maintenance. By analyzing trends and patterns in asset performance data, it can predict potential failures before they occur. This proactive approach not only minimizes downtime but also extends the lifespan of machinery and equipment.

Effective asset lifecycle management is crucial for maximizing investment returns. The PI System's detailed monitoring helps in making informed decisions regarding maintenance, upgrades, and eventual replacement of industrial assets.

Transforming how industries perceive and manage energy consumption for a sustainable future.

In today’s energy-conscious world, monitoring and optimizing energy consumption is a significant concern for industries. The PI System collects intricate data from energy meters and sensors, providing granular insights into energy usage.

The system’s ability to analyze and report on energy data is instrumental in optimizing consumption patterns. By identifying areas of excessive energy use, businesses can implement strategies to reduce consumption, leading to significant cost savings and environmental benefits.

The PI System enables a strategic approach to energy management. With its comprehensive data collection and analysis capabilities, companies can make data-driven decisions to enhance their energy efficiency and reduce their carbon footprint.

Ensuring sustainable operations through meticulous environmental tracking and adherence to regulations.

Tracking emissions, water usage, and other environmental factors is increasingly critical. The PI System provides detailed monitoring of these parameters, helping companies understand and minimize their environmental impact.

Adhering to environmental regulations is not only a legal requirement, but also a corporate responsibility. The PI System assists in ensuring compliance, thereby protecting businesses from potential fines and reputational damage.

By leveraging the PI System for environmental monitoring, companies can move towards more sustainable operations. This shift not only benefits the environment but also aligns with the growing consumer demand for environmentally responsible practices.

Advancing quality, compliance, and efficiency in critical healthcare and life sciences sectors.

In the pharmaceutical and life sciences sector, maintaining product quality and compliance with stringent regulations is crucial. The PI System offers robust data management capabilities, ensuring that manufacturing processes are monitored and controlled to adhere to quality standards.

Tracking batch data is vital in pharmaceutical manufacturing to maintain product quality and traceability. The PI System provides comprehensive batch data management, ensuring that each product meets the required quality specifications.

The system’s ability to monitor and control manufacturing processes in real-time is a significant advantage in the pharmaceutical industry. It ensures consistent product quality and helps in optimizing manufacturing efficiency.

Shaping the future of urban living through smart data analysis and infrastructure management.

Smart cities thrive on data. The PI System plays a pivotal role in collecting and analyzing data from urban infrastructure, providing insights that are essential for efficient city management.

One of the major challenges in urban management is optimizing resource allocation. The PI System aids in analyzing data to make informed decisions regarding public services, ensuring that resources are utilized efficiently.

The integration of the PI System in smart city planning enhances overall urban efficiency. By providing real-time data and insights, it helps city planners and administrators make informed decisions that improve the quality of life for residents.

InCentrik is at the forefront of transforming industrial operations. Our expertise lies in harnessing the power of advanced analytics and real-time data to revolutionize how industries manage and monitor their assets. Here’s how our innovative solutions contribute to enhancing operational excellence:

At InCentrik, we understand the importance of staying ahead in a rapidly evolving industrial landscape. Our Remote Monitoring and Diagnostics (MD) solution embodies this by providing expert-designed solutions that streamline processes and optimize performance. We offer tailor-made remote diagnostics, backed by a dedicated team committed to constant innovation and proactive support.

InCentrik's partnership with AVEVA allows us to enhance our customer support by delivering end-to-end solutions from a single point of entry, expand our reach to new end-users, and combine our capabilities with others in the AVEVA partner network to optimize our services.

With over 50 years of experience, AVEVA is the global leader in industrial engineering, design and information management software. We’ve earned our reputation through innovation, collaboration and the success of our ever-growing portfolio of software solutions.

A worldwide network of partners with AVEVA applications and support is the key to increasing our service opportunities and growing your business cost-effectively.

As part of the AVEVA Partner Network, we can take advantage of a multi-tiered support system that recognizes our delivery capabilities, level of experience, and certifications with our software and industry-related expertise.

What You Need to Know About The Integrated Remote Operations Center (iROC) - Integrated Remote Operations Center 'iROC' are becoming popular as organizations seek ways to improve efficiency and costs. Here's what you need to know.

AVEVA PI System Empowers the Mining Industry to Reduce Costs and Enhance ROI - Explore how Incentrik, partnered with AVEVA, can elevate your mining projects with tailored solutions, efficiency, and innovation

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently. Checkout our Smart Apps including the Crisis Communication App, SmartHub and SmartHub Apps OEE, Shift, PI, Rounds, and Permits.

Connect with your industrial community and colleagues at the AVEVA World Partner & Product Expo. Engage with experts, deepen your technical...

In the rapidly evolving industrial landscape, the importance of digital transformation cannot be overstated. At the heart of this transformation is...

Today's discussion delves into how automation and control systems can navigate these challenges, optimizing the transloading process, and ensuring...