The Benefits of AVEVA PI Training: Unlocking Efficiency and Innovation

In the rapidly evolving industrial landscape, the importance of digital transformation cannot be overstated. At the heart of this transformation is...

4 min read

![]() The InCentrik Team

Oct 24, 2023 1:32:04 PM

The InCentrik Team

Oct 24, 2023 1:32:04 PM

At InCentrik, we believe in creating innovative solutions that revolutionize how our customers maintain and optimize their operational machinery.

Our latest solution, BearingMD, is an exceptional software designed to address a common, yet critical issue many industrial plants face - monitoring and maintaining their bearings' performance.

BearingMD, short for 'Bearing Monitoring and Diagnostics', capitalizes on the crucial role bearings play in various machinery operations. The performance of fans, pumps, compressors, circulators, motors and more heavily relies on the efficiency of bearings.

Our solution, embedded in the Monitoring and Diagnostics services of iROC (Integrated Remote Operations Center), leverages the powerful analytical capabilities of PI Asset Framework and PI Vision to effectively monitor bearing conditions, simplifying your data analysis and condition tracking tasks.

To fully appreciate the value that BearingMD brings, it's important to take a step back and consider the crucial role of bearings in industrial operations. Bearings are elementary yet fundamental components present in a wide array of machinery, including fans, pumps, compressors, and motors. Their core function, reducing friction and facilitating smooth rolling motion, is essential to the overall efficiency and operational capability of the machinery they are housed in. These components play an especially critical role in facilities where high performance is essential, such as AI data centers, which require precision infrastructure to support high-density workloads and 24/7 uptime.

The health and performance of these bearings directly affect the operation of equipment, and by extension, the entire production process. When a bearing starts experiencing problems, it impacts the efficiency of the machine it resides in, which can cause cascading effects across the production line. Unaddressed issues can potentially lead to equipment breakdowns, necessitating unplanned downtime and expensive repairs.

The narrative of a major industrial methanol producer serves as a stark illustration of this issue. A single overlooked compressor radial bearing led to significant complications, resulting in the plant shutting down for three weeks. This minor, preventable problem escalated into a significant operational and financial crisis, causing a production loss amounting to a staggering $20M.

BearingMD is designed to prevent such calamities from occurring. This powerful tool provides real-time monitoring and diagnostics of bearing conditions, allowing plant operators and engineers to spot potential issues before they escalate into substantial problems. The software provides timely alerts when operational parameters deviate from established norms, ensuring that you have the information needed to prevent failures and maintain the overall health of your machinery.

With BearingMD, you'll no longer be in the dark about the state of your bearings. Instead, you'll be empowered with actionable insights that facilitate proactive maintenance, reduce downtime, and enhance operational efficiency. Ultimately, BearingMD is not just about keeping your bearings in check—it's about safeguarding your production process, your equipment, and your bottom line.

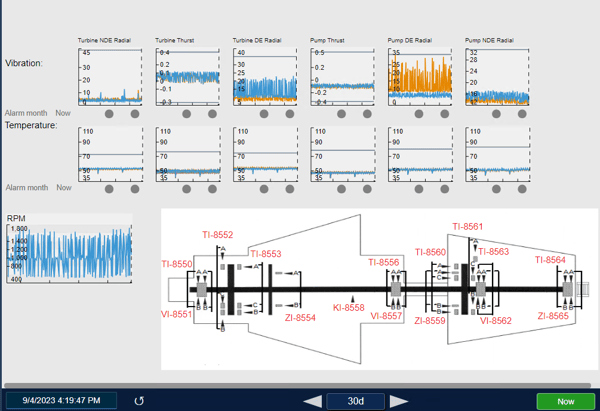

Our solution enables comprehensive monitoring of any type of bearing in any equipment, creating an array of vibration and temperature alarms based on past maintenance records and real-time operational data. These alarms are intuitively presented on PI Vision, providing end users with an easily interpretable and actionable overview of the bearing conditions.

Vibration alarms include multiple parameters such as high and low alarms, historical deviations, and check values comparing with data from 30 days prior. Similarly, temperature alarms feature high alarms and historical limit exceedances. For ease of operation, we consolidate all alarms into two categories - "Now" and "Past 30 days".

Beyond individual bearing tracking, BearingMD also provides a 'Bearing Summary Page' offering an overview of all bearings' health. This reduces the time spent checking each bearing's display and provides a comprehensive snapshot of the entire bearing fleet's condition.

Adopting BearingMD offers numerous advantages. If you are already operating a PI Server, you won't need to purchase a separate license for this software - enhancing your monitoring capabilities without adding to your operational costs. By tracking your bearings' health, you indirectly ensure the well-being of the entire machinery, leading to better performance and uptime, consequently optimizing your process and production rate.

Perhaps the most significant benefit is the predictive capability this solution offers. BearingMD allows you to identify and address any bearing performance issue at the earliest stage, thereby preventing potentially catastrophic machine failures, plant outages, and production loss.

At InCentrik, we're committed to helping you maintain and optimize your equipment's health, and ultimately your bottom line. BearingMD is just another step towards our goal of delivering world-class, innovative solutions for industrial plants. Whether you are a process engineer, IT or OT professional, or even just exploring options, BearingMD has something to offer. Take the next step towards predictive maintenance and increased operational efficiency today with BearingMD .

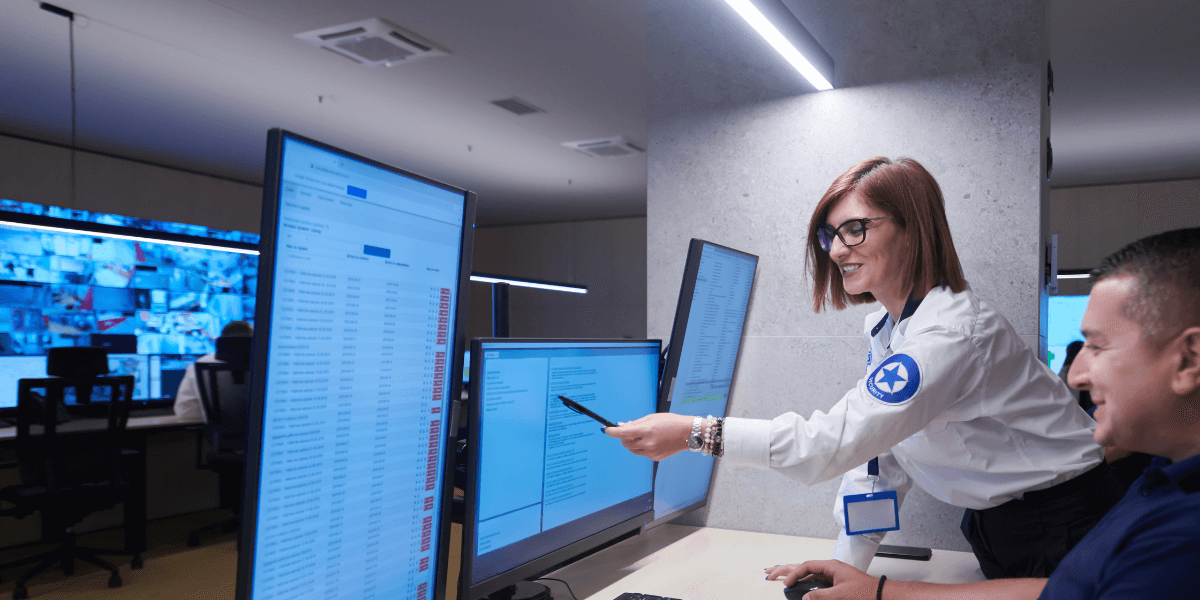

iROC (Integrated Remote Operations Center) is a centralized location from which an organization can remotely manage and monitor its critical operations in real-time. iROC allows organizations to improve operational efficiency, reduce costs, and improve security by consolidating multiple remote operations into a view.

Ready to revolutionize your maintenance practices with BearingMD ? We at InCentrik are here to support your journey towards optimal operational efficiency. Whether you are an automation engineer, an IT or OT professional, a long-term InCentrik customer, or exploring our services for the first time, we are excited to introduce you to the transformative potential of BearingMD.

Contact us today for more detailed information about BearingMD or to schedule a personalized demonstration.

What You Need to Know About The Integrated Remote Operations Center (iROC) - Integrated Remote Operations Center 'iROC' are becoming popular as organizations seek ways to improve efficiency and costs. Here's what you need to know.

Monitoring and Diagnostics with Valve MD - Let's explore the features of Valve MD and how they can help you track and analyze control valve data and monitor their condition.

Automation and Control Systems for LNG: Shifting ISO Tank Transloading - Explore how automation and control systems optimize LNG transloading, overcome logistical challenges, and ensure high-quality supply

PI System Monitoring with PI MD - PI MD is a system that helps administrators collect, organize and understand data from their infrastructure, PI system components and related applications.

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently.

In the rapidly evolving industrial landscape, the importance of digital transformation cannot be overstated. At the heart of this transformation is...

iROC (Integrated Remote Operations Center) is becoming increasingly popular as organizations look for ways to improve operational efficiency and...

When we talk about the power generation industry, one of the paramount aspects that contribute to its efficiency and cost-effectiveness is the heat...