PI System Monitoring with PI MD

With PIMD, administrators can monitor their PI System with an easy-to-use web interface. This allows them to see how their system is performing and...

If you are a process engineer, you know that monitoring and diagnostics is critical to keeping your process running smoothly. ControlMD is a great tool for monitoring and diagnostics, and it can help you identify and troubleshoot issues with your process quickly and easily.

In this blog post, we will explore the features of Control MD and how they can help you improve your process operations.

ControlMD is a revolutionary solution that helps users track and analyze their control valve data and monitor the valve's health condition. With ControlMD users can understand and monitor the health of all their control valves.

InCentrik's ControlMD solutions utilize the analytical capability and data hierarchy of the Aveva PI system and Asset Framework.

InCentrik utilizes complete maintenance records and monitors control valve performance during normal process operations, creating opportunities for improving plant integrity, efficiency, and uptime.

In a more sophisticated system, the valve can be operated by a control system that automatically adjusts the valve position in response to system operating conditions to maintain steady state control. Control valves typically have digital outputs that feed into the control system.

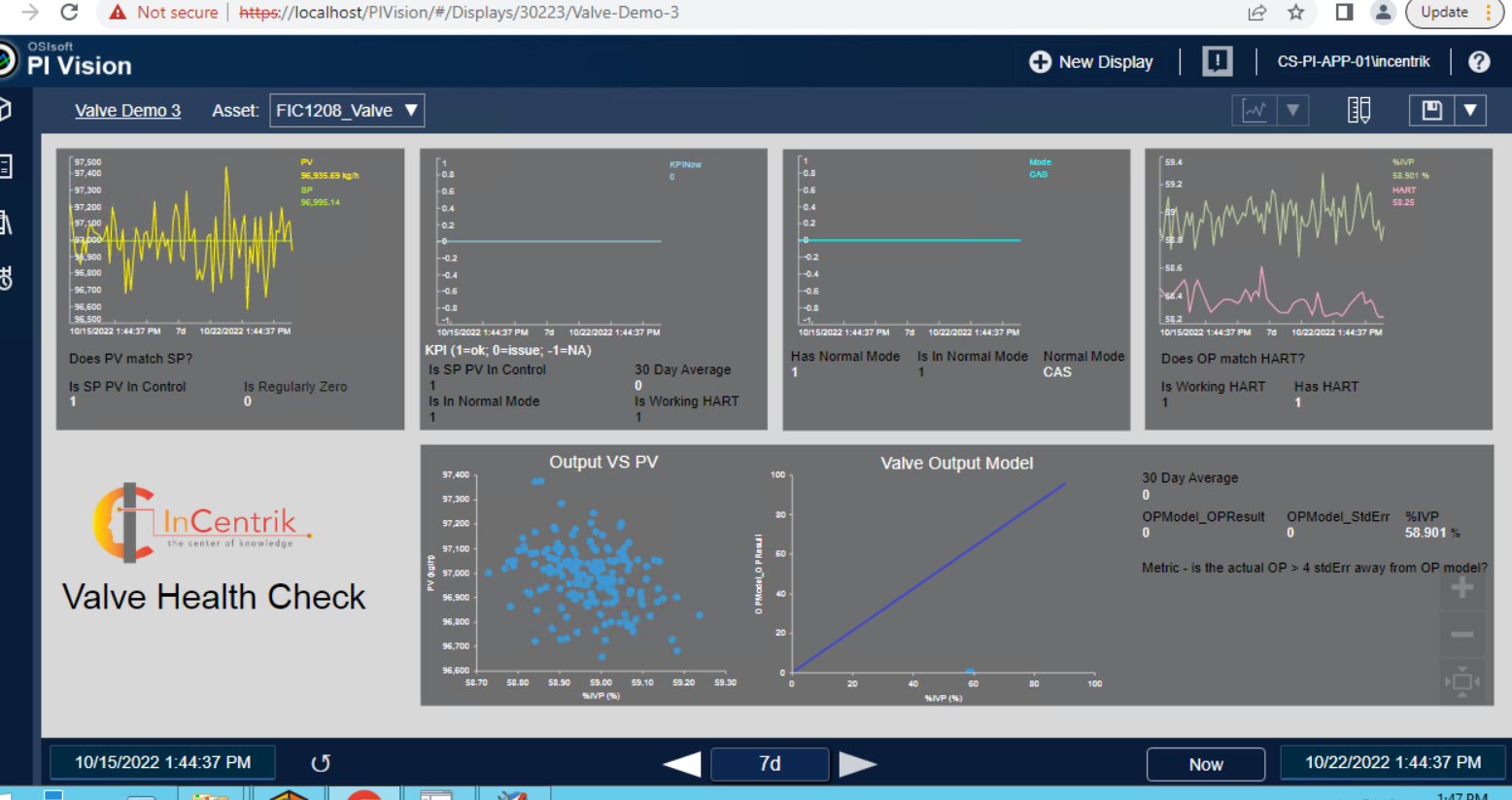

Track multiple valves across your system and give operators an instantaneous understanding of the system's performance and health condition.

InCentrik can determine if the valve is working in a healthy state or if the valve is performing poorly and must be operated manually by an operator through realtime PIVision displays.

A healthy valve control system decreases operator error, increases system efficiency, increases plant yield and quality, and generates revenue.

Implement a valve output estimation model with InCentrik's machine learning algorithms and compare to actual valve output to spot valve health issues early.

ControlMD offers the following deliverables:

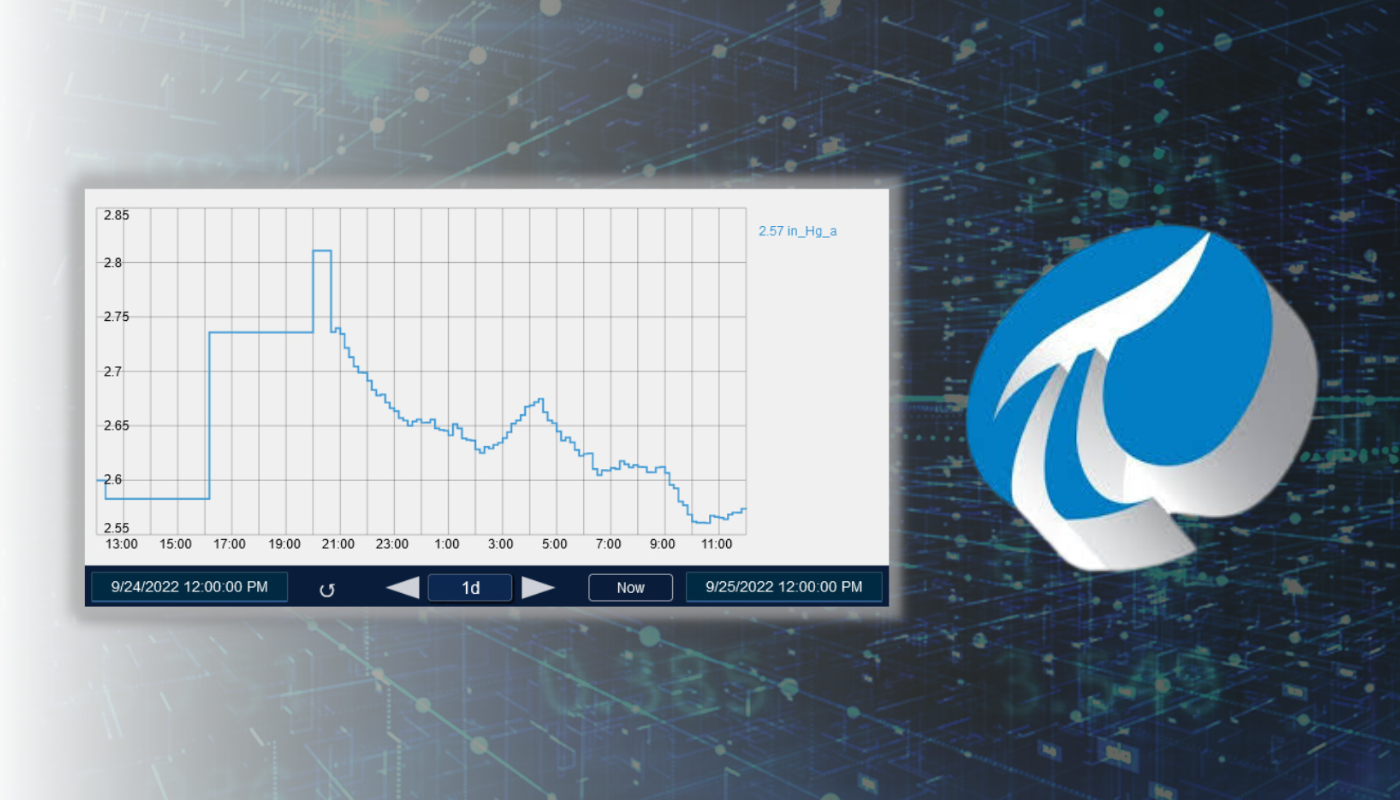

ControlMD provides real-time displays to display data, operated by OSISoft's PI Vision software.

The dashboard display includes a summary page with all the valves included in the system, showing those valves in an alarm state. Each valve graph can navigate to a detailed monitoring display for an individual valve, showing key performance indicators and individual valve operating models, where applicable.

InCentrik provides a monthly health check on all valves enrolled in ControlMD

Plot the Setpoint values (SP) and Process Variable (PV) over time to identify how these relate

Use the PV to build a model for the valve output, and see when it deviates.

Some valves have valve output positioners that will indicate the valve position.

Some benefits of that ControlMD delivers include:

ControlMD helps operators to understand and monitor the health of all their control valves, reducing errors and improving system performance.

ControlMD helps operators to confirm the valves have been installed and calibrated correctly, ensuring plant safety.

By monitoring valve performance, operators can identify and correct problems quickly to reduce downtime.

ControlMD helps operators understand what’s happening with their control valves and make necessary changes to improve the overall performance of the plant.

Contact us to learn more how InCentrik can help you track and analyze your control valve data and monitor their health condition.

iROC (Integrated Remote Operations Center) is a centralized location from which an organization can remotely manage and monitor its critical operations in real-time. iROC allows organizations to improve operational efficiency, reduce costs, and improve security by consolidating multiple remote operations into a view.

PI System Monitoring with PI MD - PI MD is a system that helps administrators collect, organize and understand data from their infrastructure, PI system components and related applications.

What You Need to Know About The Integrated Remote Operations Center (iROC) - Integrated Remote Operations Center 'iROC' are becoming popular as organizations seek ways to improve efficiency and costs. Here's what you need to know.

Automation and Control Systems for LNG: Shifting ISO Tank Transloading - Explore how automation and control systems optimize LNG transloading, overcome logistical challenges, and ensure high-quality supply

Empowering Predictive Maintenance with InCentrik’s BearingMD - Explore BearingMD by InCentrik - our cutting-edge solution for proactive bearing condition monitoring, ensuring optimal industrial operations

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently. Checkout our Smart Apps including the Crisis Communication App, SmartHub and SmartHub Apps OEE, Shift, PI, Rounds, and Permits.

With PIMD, administrators can monitor their PI System with an easy-to-use web interface. This allows them to see how their system is performing and...

In the world of data management and system efficiency, Compression MD stands out as a revolutionary tool. Developed by InCentrik, Compression MD...

When we talk about the power generation industry, one of the paramount aspects that contribute to its efficiency and cost-effectiveness is the heat...