Maximizing Power Plant Efficiency with InCentrik's HeatRate MD

When we talk about the power generation industry, one of the paramount aspects that contribute to its efficiency and cost-effectiveness is the heat...

2 min read

![]() The InCentrik Team

Jun 13, 2022 1:42:32 PM

The InCentrik Team

Jun 13, 2022 1:42:32 PM

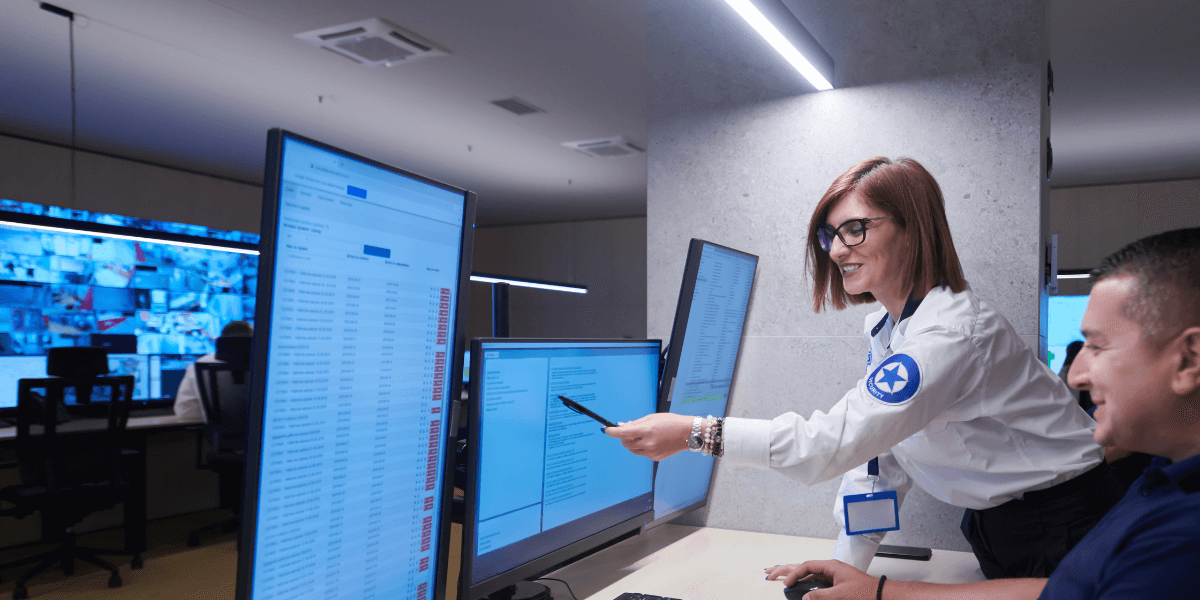

iROC (Integrated Remote Operations Center) is becoming increasingly popular as organizations look for ways to improve operational efficiency and reduce costs. If you're considering setting up an iROC, there are a few things you need to know.

Here's an overview of what iROC is and the benefits it offer:

iROC (Integrated Remote Operations Center) is a centralized location from which an organization can remotely manage and monitor its critical operations in real-time. iROC allows organizations to improve operational efficiency, reduce costs, and improve security by consolidating multiple remote operations into a view.

There are many benefits of using iROC, including:

By consolidating multiple remote operations into a consolidated data infrastructure, iROC can help organizations improve operational efficiency and reduce costs.

iROC can help organizations improve security by providing a centralized location from which to monitor and manage critical operations in real-time.

By consolidating multiple remote operations into a single view, iROC can help organizations reduce costs associated with managing and monitoring those operations.

iROC can improve situational awareness by providing real-time visibility into the status of critical operations.

iROC can improve communication and collaboration among distributed teams by providing a common platform for information sharing and decision-making.

By using iROC, organizations can improve their responsiveness to critical incidents by providing a centralized location for monitoring and managing incident response.

Organizations can meet their compliance requirements by providing a centralized location for monitoring and managing critical operations, by using iROC.

InCentrik's program can help seamlessly integrate operations for your business success in a variety of industries including manufacturing, fabrication, engineering, and more. Our Remote Operations Center services provide the tools and support needed to keep your team connected and productive, no matter where they are in the world.

Align operations and business intelligence with industry-leading collaboration. Our multi-industry experts build and maintain custom solutions, provide around-the-clock support, and drive continuous improvement towards a common goal.

Receive on-call, global support 24/7 to quickly resolve issues from wherever you are

Seamlessly organize your data infrastructure for better visualizations and effective decision making

Increase operational efficiency through digital transformation, artificial intelligence, and real-time data integration. Preferably end-to-end.

Develop personalized work environments for timely, accurate, and relevant data

Control valve health monitoring for improved plant performance. Download our brochure to learn more how InCentrik can help you track and analyze your control valve data and monitor their health condition.

Contact us for more information on how to get started.

PI System Monitoring with PI MD - PI MD is a system that helps administrators collect, organize and understand data from their infrastructure, PI system components and related applications.

Monitoring and Diagnostics with Valve MD - Let's explore the features of Valve MD and how they can help you track and analyze control valve data and monitor their condition.

Automation and Control Systems for LNG: Shifting ISO Tank Transloading - Explore how automation and control systems optimize LNG transloading, overcome logistical challenges, and ensure high-quality supply

Empowering Predictive Maintenance with InCentrik’s BearingMD - Explore BearingMD by InCentrik - our cutting-edge solution for proactive bearing condition monitoring, ensuring optimal industrial operations

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently. Checkout our Smart Apps including the Crisis Communication App, SmartHub and SmartHub Apps OEE, Shift, PI, Rounds, and Permits.

When we talk about the power generation industry, one of the paramount aspects that contribute to its efficiency and cost-effectiveness is the heat...

With PIMD, administrators can monitor their PI System with an easy-to-use web interface. This allows them to see how their system is performing and...

Today's discussion delves into how automation and control systems can navigate these challenges, optimizing the transloading process, and ensuring...