Enhancing PI Systems with Compression MD

In the world of data management and system efficiency, Compression MD stands out as a revolutionary tool. Developed by InCentrik, Compression MD...

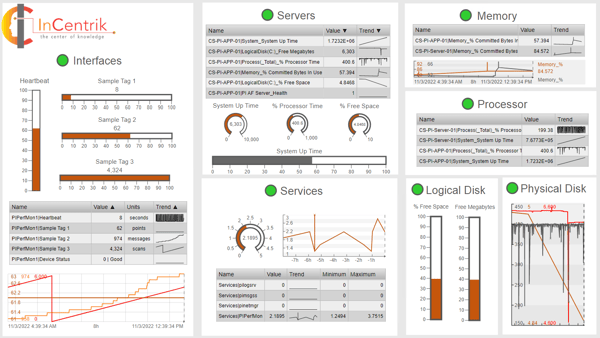

With PIMD, administrators can monitor their PI System with an easy-to-use web interface. This allows them to see how their system is performing and quickly troubleshoot any issues.

Let's dive into the details on how PIMD can enable manufacturers to get a complete picture of how their PI system is functioning and the benefits of using it.

PIMD is a system that helps administrators collect, organize and understand data from their infrastructure, PI system components and related business applications.

The PIMD system monitors the health of every aspect of the PI System, as well as maintaining computer health (disk space, memory use, processor time, etc.) for machines with PI System components installed. If any irregularities are found, notifications including details about the problem are sent by email. System components can be monitored in cloud, on-premise, and hybrid environments.

Thanks to the immediate notifications, administrators can quickly identify errors and solve them.

PIMD is based on off-the-shelf components of the OSISoft PI system. This means that administrators do not need to purchase any additional licenses to manage the system. All diagnostic data is organized within the PI AF Database.

The structure is divided into key areas reflected in PI Vision visualizations. As part of the AF Structure, analyses and event frames are configured, which give administrators a broader picture of their system functioning.

Additionally, as part of the AF model a set of configurable PI notifications about alarm events and anomalies are prepared.

PIMD can be deployed onto the customer's existing PI system.

The system consists of four main areas:

This involves the acquisition and monitoring of diagnostic data from components and services.

Similarly, this area involves the acquisition and monitoring of diagnostic data from servers and network infrastructure.

PI also consists of the acquisition and monitoring of diagnostic data of business applications such as reporting system, and data warehouse.

Lastly, PIMD consists of monitoring of connections to a system with a division into technologies and methods of authentication.

With PIMD, administrators can:

Contact us to learn more how InCentrik and PIMD can help you PIMD, administrators can monitor their PI System with an easy-to-use web interface.

iROC (Integrated Remote Operations Center) is a centralized location from which an organization can remotely manage and monitor its critical operations in real-time. iROC allows organizations to improve operational efficiency, reduce costs, and improve security by consolidating multiple remote operations into a view.

What You Need to Know About The Integrated Remote Operations Center (iROC) - Integrated Remote Operations Center 'iROC' are becoming popular as organizations seek ways to improve efficiency and costs. Here's what you need to know.

Monitoring and Diagnostics with Valve MD - Let's explore the features of Valve MD and how they can help you track and analyze control valve data and monitor their condition.

Automation and Control Systems for LNG: Shifting ISO Tank Transloading - Explore how automation and control systems optimize LNG transloading, overcome logistical challenges, and ensure high-quality supply

Empowering Predictive Maintenance with InCentrik’s BearingMD - Explore BearingMD by InCentrik - our cutting-edge solution for proactive bearing condition monitoring, ensuring optimal industrial operations

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently. Checkout our Smart Apps including the Crisis Communication App, SmartHub and SmartHub Apps OEE, Shift, PI, Rounds, and Permits.

In the world of data management and system efficiency, Compression MD stands out as a revolutionary tool. Developed by InCentrik, Compression MD...

When we talk about the power generation industry, one of the paramount aspects that contribute to its efficiency and cost-effectiveness is the heat...

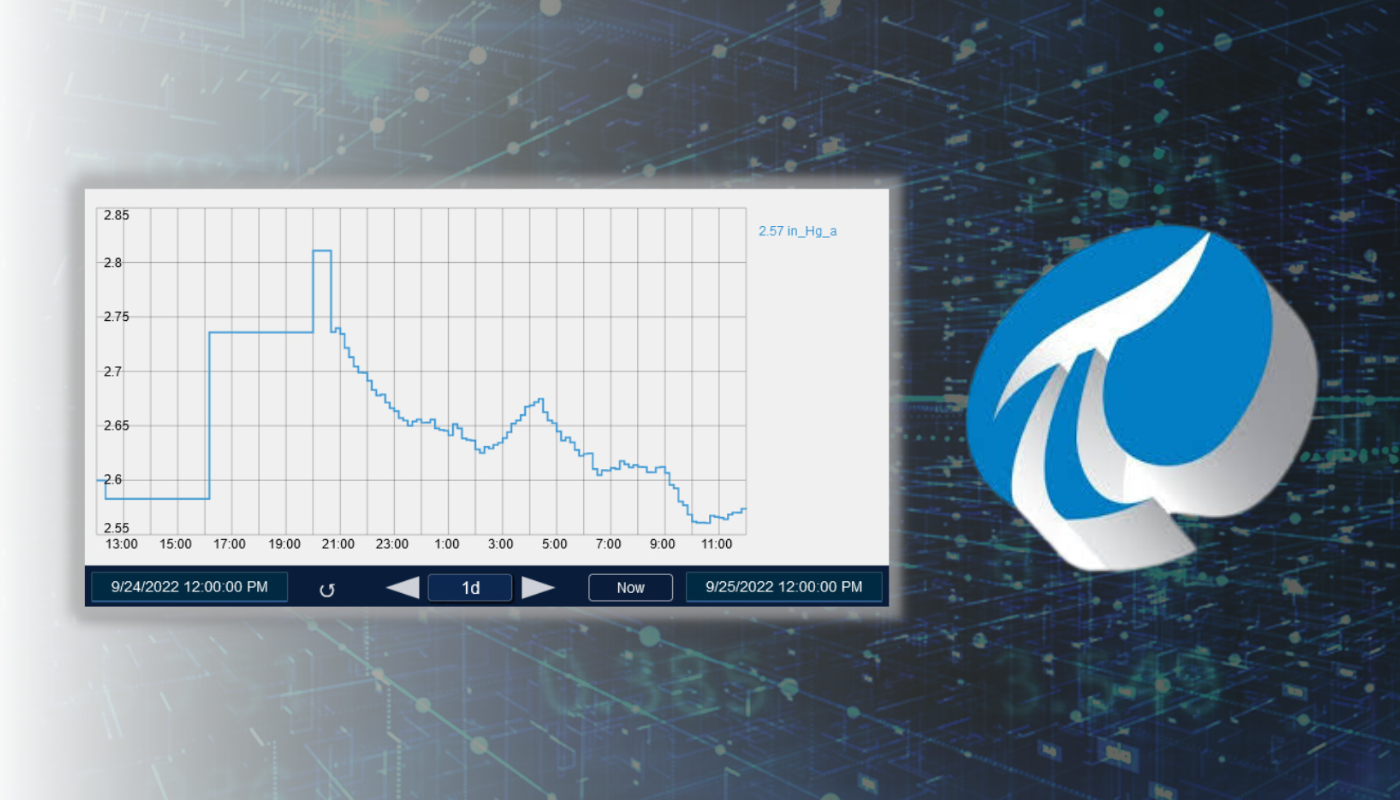

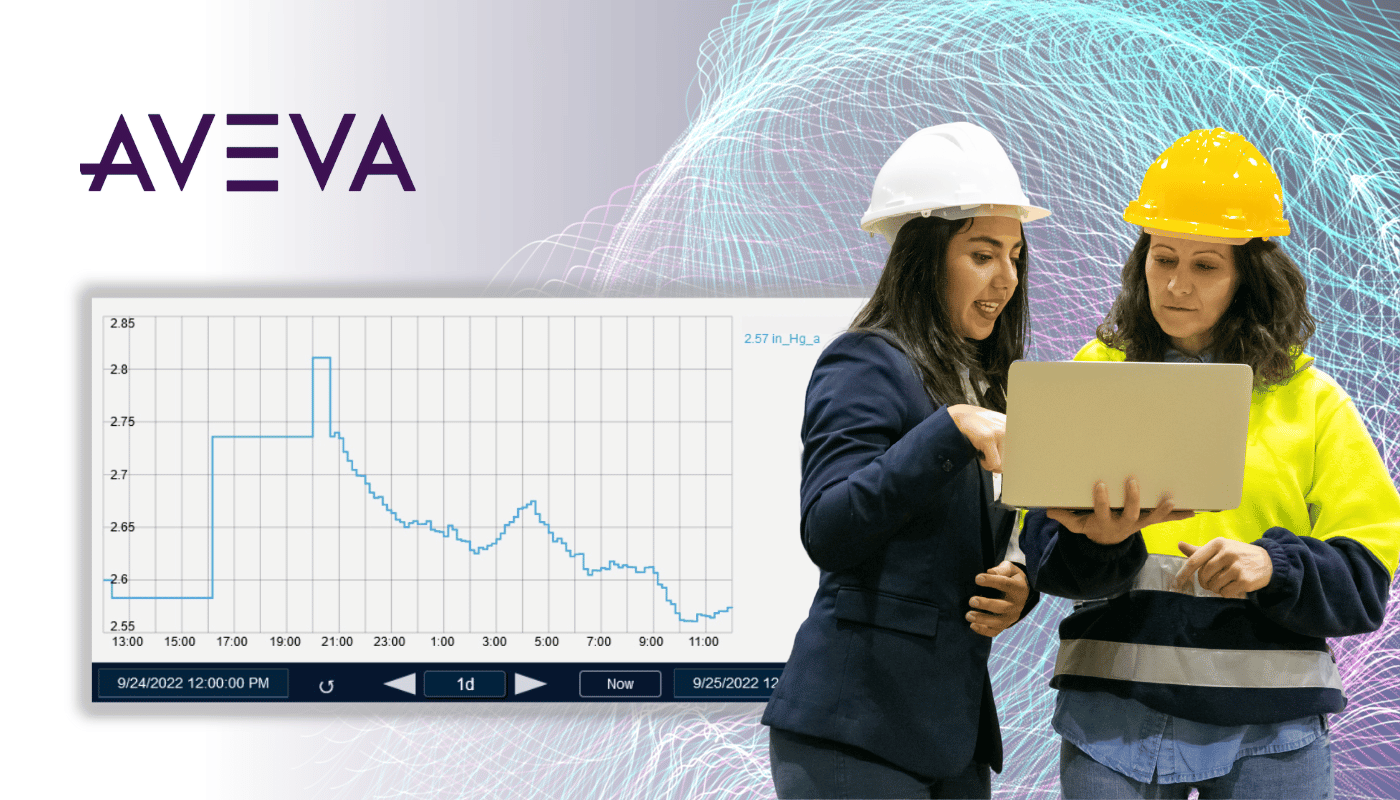

In the realm of industrial automation and data management, AVEVA's PI System (formerly OSIsoft's PI System) stands out as a pivotal technology. As...