10 Key Differences Between ERP and MES Systems

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) share some common purposes in the manufacturing environment. The two...

5 min read

![]() The InCentrik Team

Sep 9, 2024 12:38:26 PM

The InCentrik Team

Sep 9, 2024 12:38:26 PM

The oil and gas sector, historically known for its heavy reliance on physical labor and mechanical processes, is undergoing a seismic shift due to the industry's progression towards digitization. This shift is not just about adopting new technologies; it’s about revolutionizing how the entire sector operates from the ground up.

Here, we delve deep into what digital transformation means for the oil and gas industry, exploring its challenges, benefits, and real-life examples that illustrate the transformative power of data and digital technologies.

Digital transformation in the oil and gas industry refers to the integration of data and digital technology into all areas of business, fundamentally changing how companies operate and deliver value to customers.

It's not merely about converting analog processes to digital ones; it’s about using technology to create new — or modify existing — business processes, culture, and customer experiences. This encompasses everything from data analytics and the Internet of Things (IoT) to artificial intelligence (AI) and blockchain.

In an era where digital technologies are revolutionizing industries across the globe, the oil and gas sector is no exception. Digital transformation is not just a trend but a crucial step toward optimizing operations, enhancing efficiency, and ensuring sustainability. However, this transformation comes with its own set of challenges.

Despite the clear advantages, the journey towards digital transformation is fraught with challenges. According to McKinsey, a staggering 70% of digital transformation initiatives fail to go beyond the pilot stage. Here’s why:

Updating Legacy Systems: Many oil and gas IT and OT infrastructures are built on outdated technology. Transitioning these systems to modern, connected platforms is a complex, resource-intensive process that requires significant change management efforts and can meet resistance from within.

Cost of Technology: The initial investment in digital transformation can be substantial. Justifying the costs and ensuring a positive return on investment (ROI) can be challenging. Companies need to strategically plan their digital initiatives to maximize ROI.

End-User Training and Upskilling: Implementing new technologies demands a workforce that is proficient in them. This requires extensive training and support, and a continuous learning culture to adapt to ongoing technological advancements. Change is often met with resistance, and the oil and gas industry is no different. Employees accustomed to traditional methods may be reluctant to adopt new technologies. Overcoming this cultural barrier requires comprehensive training and change management strategies.

Cybersecurity and Regulatory Compliance: As operations digitalize, they become targets for cyber-attacks. Moreover, digital tools must be compliant with the myriad of regulations that vary by region and activity. Protecting critical infrastructure from cyber threats is paramount, and the industry must invest in advanced cybersecurity solutions to safeguard against potential breaches.

Data Management: Effective digital transformation requires the ability to aggregate, analyze, and act upon vast quantities of data. This presents challenges in data integration and quality management. Managing, analyzing, and securing this data is a daunting task. Ensuring data integrity and leveraging it for actionable insights requires advanced data analytics tools and robust cybersecurity measures.

The benefits of digital transformation in the oil and gas sector are significant and varied:

Reduced Impact of Price Volatility: Digital tools like machine learning and AI enhance the ability to predict market changes and respond proactively, thus mitigating the risks associated with price fluctuations.

Enhanced Change Management: Digital solutions facilitate better management of organizational change by providing tools that support effective communication and timely information sharing.

Accelerated Carbon Reduction: Digital technologies help in optimizing resource use and reducing emissions, aligning operational processes with environmental sustainability goals.

AI-Powered Safety Management: AI applications analyze historical incident data to predict and prevent potential risks, significantly improving safety outcomes.

Blockchain for Supply Chain Transparency: Blockchain technology offers a secure, transparent way to manage complex supply chains, enhancing efficiency and compliance.

Cloud Computing: Cloud platforms support scalable data storage and advanced analytics, enabling real-time decision-making and operational flexibility.

Predictive Maintenance: Using data analytics to predict equipment failures before they occur minimizes downtime and reduces maintenance costs.

Exploration Software: Advanced software applications use machine learning to improve the accuracy of exploration activities, reducing the risk and cost of drilling.

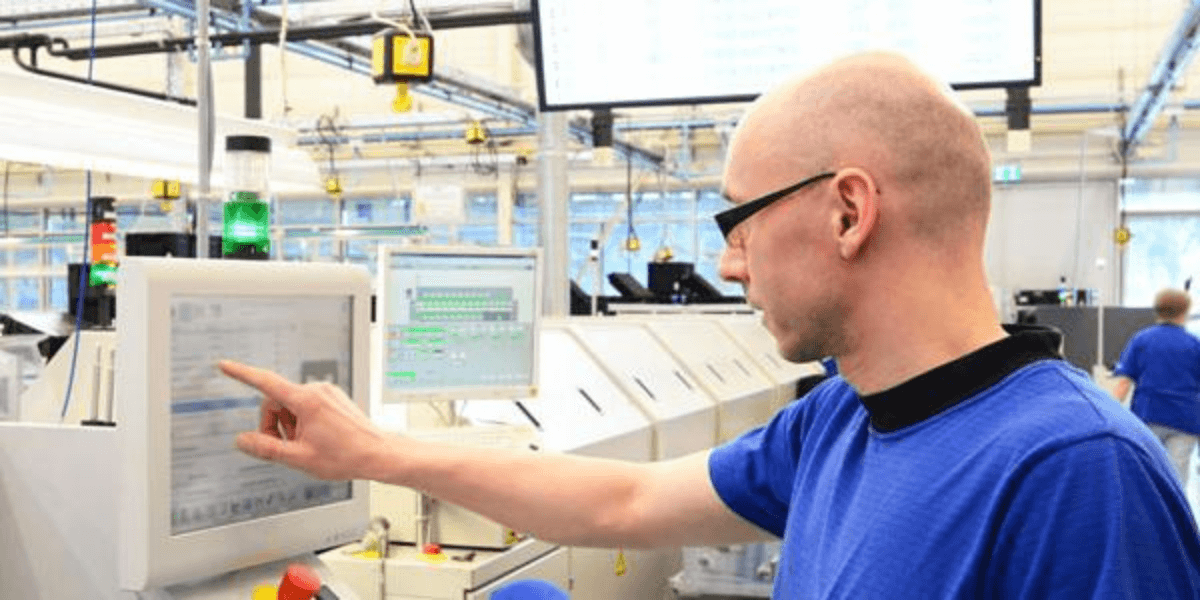

Manufacturing Execution Systems (MES): Manufacturing Execution Systems provide real-time monitoring of production processes, improving quality control and operational efficiency.

BP’s Advanced Analytics: BP has leveraged advanced analytics to optimize its operations. By implementing a data-driven approach, the company has improved asset reliability and performance, leading to significant cost savings and enhanced productivity.

Shell’s IoT and AI Integration: Shell has embraced IoT and AI technologies to enhance its exploration and production activities. Real-time data from IoT sensors combined with AI-driven analytics has enabled Shell to make more accurate predictions and optimize its drilling operations.

ExxonMobil’s Remote Monitoring: ExxonMobil has implemented remote monitoring solutions across its operations. By using IoT and cloud-based technologies, the company can monitor its assets in real-time, leading to improved safety, reduced downtime, and optimized performance.

Chevron’s Digital Twin Technology: Chevron has adopted digital twin technology to create virtual replicas of its physical assets. This allows for real-time monitoring and simulation, enabling the company to optimize maintenance schedules, improve safety, and enhance operational efficiency.

The future of the oil and gas industry lies in leveraging these digital advancements to drive efficiency, enhance safety, and support sustainable practices.

While the path to digital transformation in the oil and gas industry is complex and fraught with challenges, the potential rewards are substantial. Companies like InCentrik are at the forefront, providing the tools and expertise needed to navigate this transformative journey successfully. Our expertise lies in harnessing the power of advanced analytics and real-time data to revolutionize how industries manage and monitor their assets.

At InCentrik, we understand the importance of staying ahead in a rapidly evolving industrial landscape. Our Remote Monitoring and Diagnostics (MD) solution embodies this by providing expert-designed solutions that streamline processes and optimize performance. We offer tailor-made remote diagnostics, backed by a dedicated team committed to constant innovation and proactive support.

Ready to revolutionize your operations with iROC? Contact us today to learn how InCentrik's Integrated Remote Operations Center (iROC) services can streamline your processes, boost efficiency, and drive innovation. Our team is here to guide you through every step of your digital transformation journey.

Get in touch now to start your iROC experience!

What You Need to Know About The Integrated Remote Operations Center (iROC)- Integrated Remote Operations Center 'iROC' are becoming popular as organizations seek ways to improve efficiency and costs. Here's what you need to know.

6 Top Use Cases for AVEVA PI System (Formally OSIsoft) - Explore AVEVA's PI System's (formally OSIsoft) impact on industries with six key use cases in automation and data management.

AVEVA PI System Empowers the Mining Industry to Reduce Costs and Enhance ROI - Explore how InCentrik, partnered with AVEVA, can elevate your mining projects with tailored solutions, efficiency, and innovation

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) share some common purposes in the manufacturing environment. The two...

In the rapidly evolving landscape of industrial and manufacturing technologies, the convergence of digital and physical systems has given rise to...

In the rapidly evolving industrial landscape, the importance of digital transformation cannot be overstated. At the heart of this transformation is...