1 min read

How Digital Transformation is Revolutionizing Industry 4.0

Industry 4.0 is the term used to describe the fourth industrial revolution. It is the fusion of physical and digital technologies that are...

4 min read

![]() The InCentrik Team

Oct 24, 2022 9:38:28 AM

The InCentrik Team

Oct 24, 2022 9:38:28 AM

Did you know that manufacturers have their own specific types of software systems? Manufacturing Execution Systems (MES) are one type of software used by manufacturers to help with the production process. MES helps optimize and manage the flow of materials through the manufacturing process.

Let's review what MES are and how they can help your business.

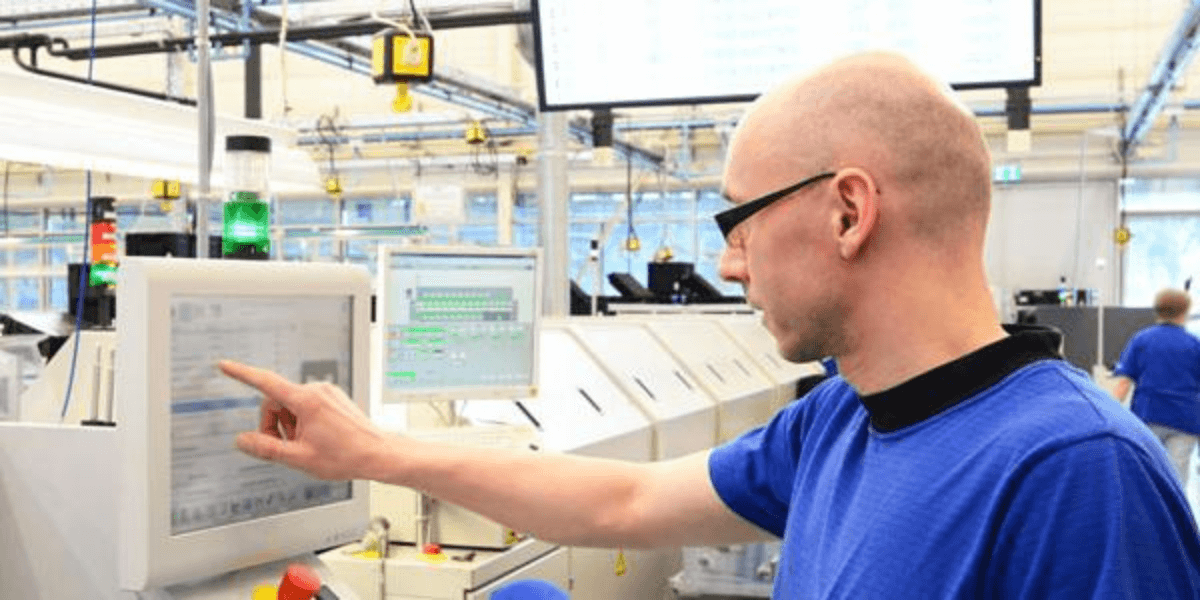

Manufacturing Execution Systems (MES) are computer systems that provide visibility and control over the manufacturing process, like for metal sheet cutting. They are used to tracking production progress, schedule production activities, and monitor equipment performance. MES systems typically interface with enterprise resource planning (ERP) and other business systems to exchange data and information.

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) share some common purposes in the manufacturing environment. The two systems are similar enough that their unique characteristics are easy to overlook. It is helpful, therefore, to examine some of the dissimilarities between the two.

MES systems can be used in a variety of manufacturing industries, including food and beverage, pharmaceuticals, automotive, electronics, and more. MES systems can be deployed using on-premise, cloud-based, or hybrid models.

On-premise MES systems are installed and operated within the manufacturing facility. Cloud-based MES systems are hosted off-site and delivered to users via the internet. Hybrid MES systems are a combination of on-premise and cloud-based deployments.

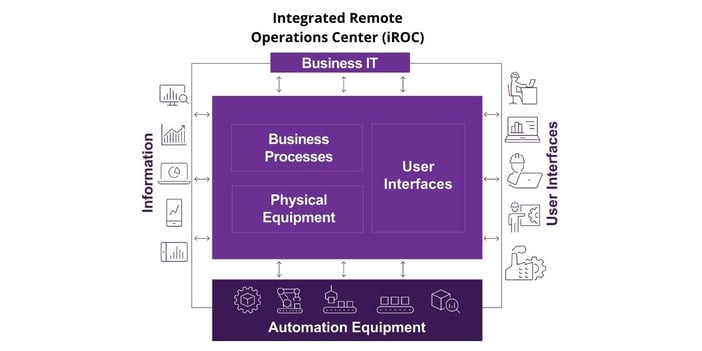

Manufacturing Execution Systems (MES) integrate live production information from a variety of locations, as well as equipment, controllers, and business applications. With transparency, control, and overall manufacturing optimization throughout the company, MES provides the digital backbone for Industry 4.0 and the Intelligent Enterprise.

Manufacturing execution systems (MES) provide a wide range of long-term and short-term advantages, as well as strategic and tactical benefits, including enhanced time to volume, higher yields, reduced operational expenses, and increased compliance.

Additional benefits include

MES systems typically include the following features:

- Data collection and capture: MES systems collect data from various sources, including sensors, controllers, and business applications. The data is then stored in a central repository for analysis and reporting.

- Real-time monitoring: MES systems provide users with real-time visibility into the manufacturing process. This allows users to make proactive decisions to improve production efficiency.

- Production scheduling: MES systems can be used to schedule production activities and track production progress. This helps ensure that manufacturing operations are running smoothly and efficiently.

- Equipment monitoring: MES systems can monitor equipment performance and identify potential issues. This helps improve equipment uptime and prevent production downtime (see scheduled and emergency shutdowns).

- Quality management: MES systems can be used to manage quality control throughout the manufacturing process. This helps ensure that products meet quality standards.

- Analytics and reporting: MES systems provide users with powerful analytics and reporting capabilities. This allows users to make informed decisions about the manufacturing process.

The traditional approach to managing people is changing. Manufacturing Organizations are transforming their operations by digitally upgrading their business processes in order to provide new and enhanced products that improve profitability or increase revenue while also providing delight for clients.

The introduction of new technologies in manufacturing has resulted in a fundamental change that impacts every aspect of the business. Digital transformation of manufacturing operations significantly transforms work processes to increase productivity and performance, enhance manufacturing flexibility, guarantee quality and consumer safety, and reduce compliance costs both internally or externally imposed regulations.

AVEVA’s Model-Driven MES approach is engineered to combine the traditional benefits of a manufacturing execution system with modern digital workflow management technology to bring people, organizations, and processes together for increased efficiency as well as for capturing work processes and operational procedures in digital workflows and related user experience configurations (models).

With its methodology-centric and Model-Driven approach, AVEVA reduces end-to-end time to value and cost of ownership for manufacturing execution system (MES) installations and multi-site rollouts by digitizing operational procedures for standardization with agility to adapt to change, continuous improvement in operational efficiency, and return on MES investment.

Customers achieve the following average benefits by implementing their Manufacturing Execution System:

AVEVA’s Manufacturing Operations Management platform minimizes the risks and costs of MES deployment and reduces the time and effort for multi-site rollouts with the help of:

Make the most of your manufacturing organization by aligning people and processes with sophisticated digital technologies for a cost-effective, repeatable approach to operational excellence, compliance, transparency, and company agility.

By digitally managing business rules and capturing information for all operational activities and plant events in real time, your business can maximize profit, quality, and compliance in manufacturing.

At InCentrik, through cross-sectoral partnerships, we can develop and navigate your digital roadmap. We align your business needs with the right technology to build the perfect solution for maximizing operational efficiencies.

We have been assisting businesses and small companies in adopting a digital mindset and business operation method since Power Apps was first released. The outcomes have been amazing, to say the least.

Contact InCentrik (your Aveva Endorsed Partner) today!

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently. Checkout our Smart Apps including the Crisis Communication App, SmartHub and SmartHub Apps OEE, Shift, PI, Rounds, and Permits.

1 min read

Industry 4.0 is the term used to describe the fourth industrial revolution. It is the fusion of physical and digital technologies that are...

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) share some common purposes in the manufacturing environment. The two...

Turning raw data into actionable insights is critical for maintaining efficiency and competitiveness. InCentrik's Manufacturing Intelligence services...