AVEVA PI System Empowers the Mining Industry to Reduce Costs and Enhance ROI

AVEVA is making an indelible mark on the mining industry, earning recognition from Fastmarkets as the Technology/IT Provider of the Year for 2021....

5 min read

![]() The InCentrik Team

Apr 11, 2024 4:42:17 PM

The InCentrik Team

Apr 11, 2024 4:42:17 PM

Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) share some common purposes in the manufacturing environment. The two systems are similar enough that their unique characteristics are easy to overlook.

Although they may have similar purposes, they have some significant differences that are important to understand. In this article, we will explore the key differences between MES and ERP systems.

The primary focus of ERP systems is to provide a platform for sharing information across the organization. ERP systems are designed to integrate all aspects of a business, including finance, sales, inventory management, and customer relationship management. Acting as an overarching data pathway makes ERP a valuable tool for management since it gives decision makers the ability to dive deeply into each part of the business and tie previously far-flung data together in meaningful ways.

The reason for adding MES, on the other hand, is to provide a means for precise control of the manufacturing process. They are responsible for monitoring and controlling the production process, from the raw materials to the finished products. MES systems gather real-time data on the production process, analyze it, and generate reports that allow for corrective actions to be taken. By doing so, they help to optimize production processes, reduce waste, and increase profitability.

MES takes steps or generates reports based on what is taking place at the moment to monitor and correct variables affecting production efficiency. MES synchronizes the numerous facets of fabrication to orchestrate the best possible solution for obtaining a less wasteful and more profitable process.

The means of data capture is another significant difference between MES and ERP systems.

Humans typically feed most information into ERP. This manual data gathering works well since the system is primarily concerned with collecting, organizing and sharing information across an organization for planning and guidance. Modern ERP systems have one database for the entire organization, so redundant entries are reduced or eliminated. A single data store also makes fluid sharing of information across different functional areas a seamless process.

MES systems, on the other hand, require real-time data to monitor and control the production process.

The immediacy of manufacturing drives the need for MES. Real-time production monitoring is achieved through barcode scanner events, IoT sensor signals, data feeds from product test stations, assembly machinery sensor systems feedback, and data entry from production floor personnel. This information provides accurate and timely information to ERP, enabling the organization to react quickly enough to keep up with rapidly changing circumstances. Reducing latency in this manner increases the odds of realizing a higher monetary return on each job.

The triggers for actions are another significant difference between MES and ERP systems.

ERP performs based on financial transactions. When customers place orders, suppliers send bills or payroll issues checks, the system responds with an action. ERP is multifunctional, but developers build it around a primarily economic substructure. ERP systems are designed around an economic substructure and have a broad range of functionalities that support different aspects of the business.

MES systems, on the other hand, are process event-driven. They are designed to monitor specific events in the manufacturing process and trigger actions based on those events. For example, MES systems can ensure conformance to the production process, track inventory consumption, place holds on non-conforming material, schedule machine maintenance based on performance, and reorder procedures to utilize available resources more efficiently.

MES systems generally deal with highly granular data, often capturing information on a minute-by-minute or even second-by-second basis. For instance, they may monitor the temperature of a machine, the speed of a production line, or the quality of items being produced.

ERP systems, on the other hand, often work with aggregated data. For example, they might track total production for a day or week, or monitor revenue and expenses over a month or quarter. This means that ERP systems usually work with a higher-level view compared to the very detailed view that MES systems provide.

MES systems are more concerned with real-time or near real-time data, as they need to be able to make quick decisions and respond to issues in the manufacturing process as they occur.

ERP systems generally work with a longer time horizon. They are used for planning and analysis, and while they do deal with some real-time data (such as orders coming in), they are more focused on trends and longer-term planning.

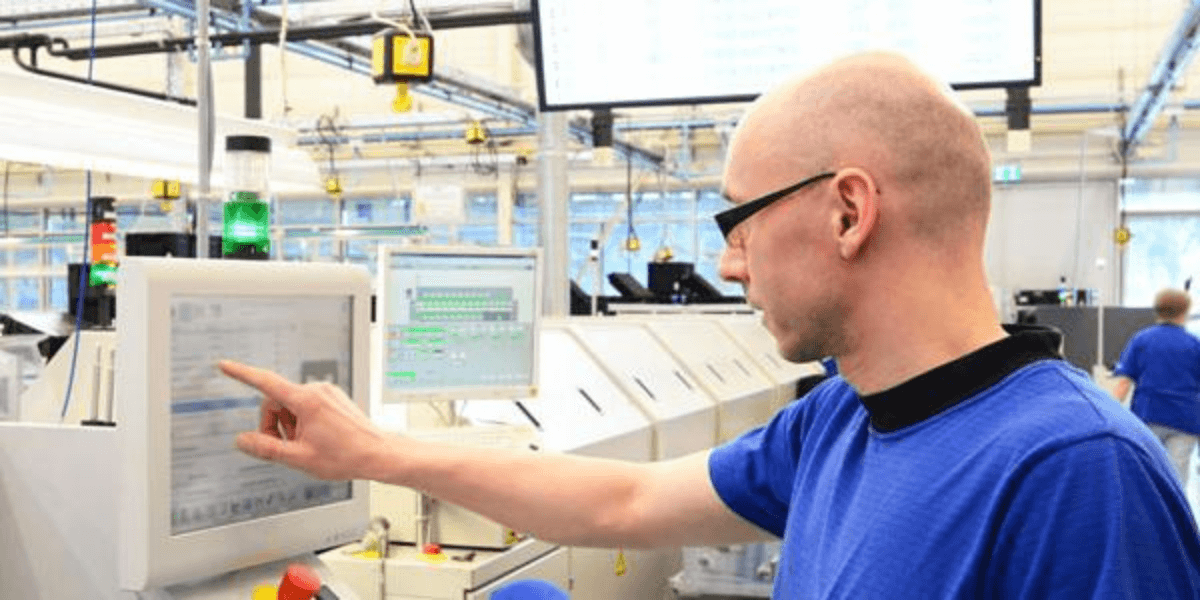

The primary users of MES systems are typically on the shop floor. This includes production supervisors, line operators, quality control personnel, and maintenance staff.

In contrast, the primary users of ERP systems are often in the office environment. This includes executives, finance professionals, sales and marketing teams, and supply chain managers.

MES systems typically need to integrate tightly with a range of shop floor systems and equipment, such as PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, and quality control equipment.

ERP systems need to integrate with a wider range of both office and shop floor systems. This might include CRM (Customer Relationship Management) systems, HR systems, finance systems, as well as some integration with shop floor systems.

MES systems often require a higher degree of customization compared to ERP systems. Since manufacturing processes can be very specific and unique, MES systems need to be able to accommodate a wide range of different equipment and processes.

ERP systems, while still customizable, are often more standardized in their features and functionalities, as the business processes they manage tend to be more uniform across different organizations.

MES systems have a direct impact on the quality of the product as they control real-time production parameters. Adjustments made by MES can directly alter the quality of the final product.

ERP systems, on the other hand, have an indirect impact on product quality through better resource planning and analysis.

MES systems often require frequent updates to adapt to changes in manufacturing processes. They need to evolve in line with improvements in production techniques, adjustments in manufacturing equipment, or alterations in product design. Hence, the lifespan of an MES application version may be shorter and may require more frequent iterations to keep up with the rapidly changing production environment.

ERP systems, on the other hand, generally have a longer lifecycle and may not require frequent updates. Changes to ERP systems often align with changes in an organization's business model, market dynamics, or regulatory requirements. ERP system updates may be substantial, requiring careful planning and significant resources, but they usually occur less frequently than MES system updates.

MES and ERP systems are both essential tools for businesses to optimize their manufacturing processes. While MES systems focus on precise control over the manufacturing process, ERP systems provide a platform for sharing information across the organization. Both systems work together to ensure the efficient and effective running of the business. With the right combination of MES and ERP systems, businesses can reduce waste, improve efficiency, and increase profitability.

By understanding the differences between MES and ERP systems, businesses can make informed decisions about which tools to use in order to achieve their desired objectives. The right combination of these two powerful solutions will ensure that all aspects of the business are operating optimally.

The bottom line is that both MES and ERP systems are essential for businesses to optimize their manufacturing processes. The differences between them should be taken into consideration in order to make the most informed decisions about which tools to use in order to achieve their desired objectives.

Original Article by Intraratio

What You Need to Know About The Integrated Remote Operations Center (iROC)- Integrated Remote Operations Center 'iROC' are becoming popular as organizations seek ways to improve efficiency and costs. Here's what you need to know.

6 Top Use Cases for Aveva PI System (Formally OSIsoft) - Explore Aveva's PI System's (formally OSIsoft) impact on industries with six key use cases in automation and data management.

AVEVA PI System Empowers the Mining Industry to Reduce Costs and Enhance ROI - Explore how Incentrik, partnered with AVEVA, can elevate your mining projects with tailored solutions, efficiency, and innovation

![]() Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

Leading the digital transformation in the manufacturing industry. We bring our customers value through automation, integration, data management, and business intelligence. We bridge the gap between what really goes on in your plant and the decision-making power you hold as an executive.

At InCentrik we automate our customers process systems, manage our customer's data (from any data source), make data available to everyone, and we bring business intelligence to the data in order for our customers to work more efficiently. Checkout our Smart Apps including the Crisis Communication App, SmartHub and SmartHub Apps OEE, Shift, PI, Rounds, and Permits.

AVEVA is making an indelible mark on the mining industry, earning recognition from Fastmarkets as the Technology/IT Provider of the Year for 2021....

In the rapidly evolving industrial landscape, the importance of digital transformation cannot be overstated. At the heart of this transformation is...

In the rapidly evolving landscape of industrial and manufacturing technologies, the convergence of digital and physical systems has given rise to...