Challenge

Manufacturing sites have many automatic controllers (typically in the hundreds or even thousands for large facilities). These controllers are designed to run in automatic mode without operator intervention.

Most sites don’t have insight into how these controllers are actually performing. Potential unknowns include, is the controller running in automatic as designed, or is an operator running the controller in manual; is the controller stable; is the controller effectively maintaining setpoint.

Poor control may result in: increased risk of safety incidents, harmful environmental impact, failure to meet product specifications, lower throughput, waste of energy and raw materials, increased maintenance costs, and increased operator intervention.

Off-the-shelf CLPM applications are currently available, but do not have a method to calculate metrics based upon different recipes, grades, operating conditions, etc. These applications are also unable to incorporate additional process data tags, such as overall production, and provide limited metrics available to users.

Solution

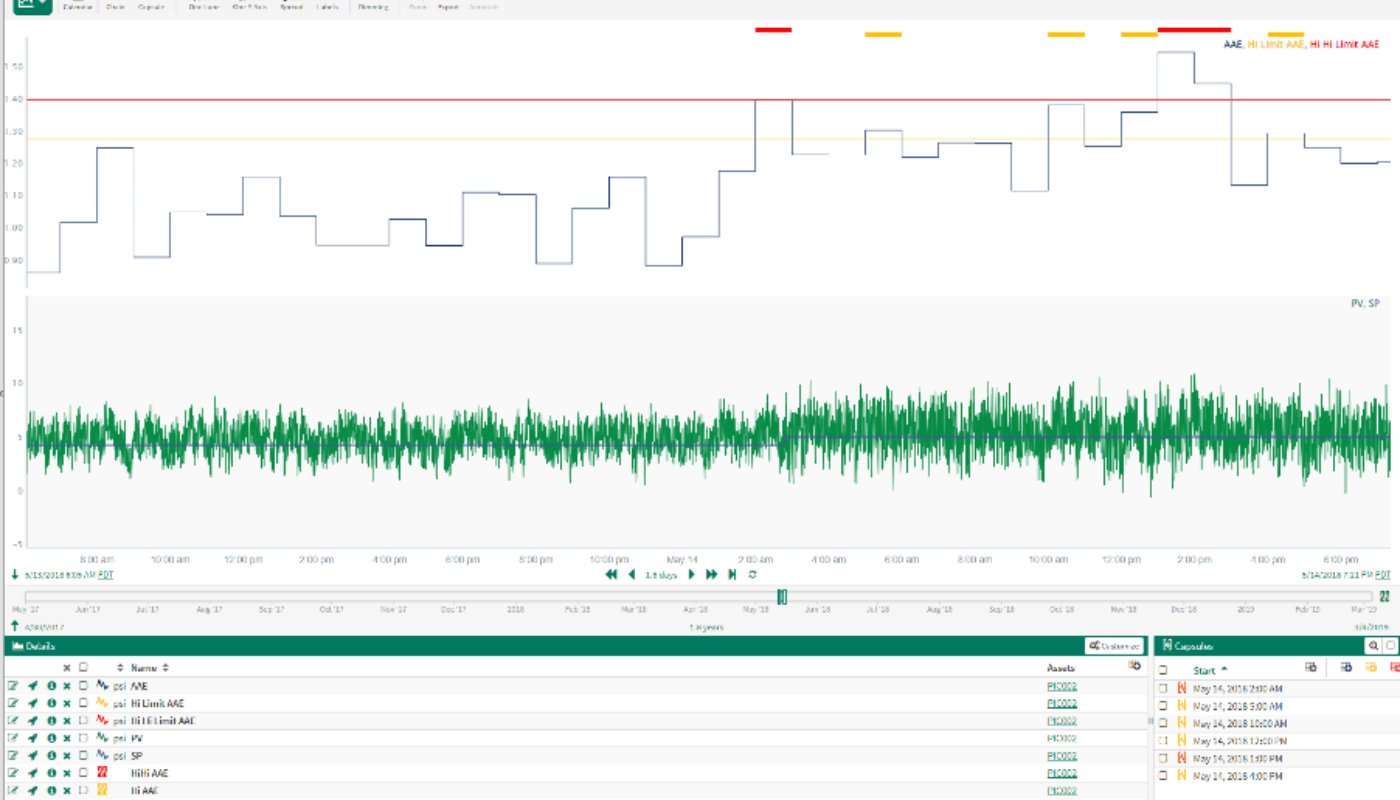

Use Seeq to calculate and monitor key controller performance metrics. These metrics are calculated based upon values from the controller: mode, controller output, setpoint, and process variable. While there are many metrics that may be calculated, a few examples include: controller error, output travel, percent time in the correct mode, setpoint changes, etc.

Seeq offers a flexible CLPM solution that can easily create conditions based upon different recipes, etc. The user has the flexibility to tie in additional process data and tags from the historian to investigate how controller performance is impacting overall unit and plant performance. Additionally, the metrics calculated for each controller are flexible and configurable by the end user.

Results

Using Seeq to monitor controller performance may reveal issues related to lack of operator training, mechanical issues, poor controller tuning / ineffective control strategy, change in operating conditions, etc.

With this insight into how controllers are performing, engineers and operators can troubleshoot the issue to optimize process performance.

InCentrik's Partnership with SEEQ

InCentrik's partnerships with Seeq allow us to provide our clients with advanced analytics solutions that are critical to their operations.

InCentrik's partnerships with Seeq allow us to provide our clients with advanced analytics solutions that are critical to their operations.

Through the partnerships, we can harness diagnostic and predictive analytics to enable greater operational efficiency and deeper insight.