8 Ways End-to-End Automation Benefits Operational Excellence

In today's competitive landscape, businesses need to find ways to operate more efficiently and effectively in order to stay ahead of the curve. By...

4 min read

![]() The InCentrik Team

Jul 25, 2024 8:56:20 AM

The InCentrik Team

Jul 25, 2024 8:56:20 AM

In an era of escalating cyber threats and heightened geopolitical tensions, the security of industrial control systems (ICS) has never been more critical. Rockwell Automation, a leader in industrial automation and information, has issued an urgent notice reiterating the need for robust cybersecurity measures.

This blog post delves into the advisory from Rockwell Automation, emphasizing the critical actions required to protect industrial devices from cyber threats.

Rockwell Automation's advisory is clear and unequivocal: customers must immediately assess their devices to determine if they are exposed to the public internet. If any devices not specifically designed for public internet connectivity are found, they must be disconnected urgently. This measure is crucial in reducing the attack surface and mitigating the risk of unauthorized and malicious cyber activity.

The backdrop of this advisory is the increasing global cyber activity driven by geopolitical tensions. Adversarial nations and cybercriminal groups are constantly probing for vulnerabilities in industrial systems. By exposing devices to the public internet, companies inadvertently provide an entry point for these threat actors.

Rockwell Automation advises that no device not specifically designed for public internet connectivity should ever be configured to be directly connected to the public-facing internet. This proactive measure is fundamental in reducing the exposure to potential cyber threats.

To assist customers in identifying and disconnecting exposed assets, Rockwell Automation and the Cybersecurity and Infrastructure Security Agency (CISA) have provided several valuable resources:

Disconnecting devices from the public internet can be straightforward but requires careful planning and execution. Here are the essential steps:

Disconnecting devices from the public internet is a critical step, but it's not the only measure needed to secure your ICS environment. Rockwell Automation emphasizes the importance of following comprehensive security best practices:

Rockwell Automation also highlights the importance of addressing known vulnerabilities. Customers should be aware of the following related Common Vulnerabilities and Exposures (CVEs) and ensure that mitigations are in place where possible:

A single security measure is rarely sufficient to protect against the sophisticated cyber threats targeting industrial control systems. A layered security strategy is essential, combining multiple defenses to create a robust security posture. This approach includes:

Given the complexity of securing industrial control systems, collaborating with cybersecurity experts can be invaluable. Rockwell Automation offers a range of services to help customers enhance their security posture, including risk assessments, security consulting, and managed security services.

The security advisory from Rockwell Automation serves as a stark reminder of the critical importance of cybersecurity in the industrial sector. In a world where cyber threats are ever-evolving and increasingly sophisticated, taking proactive measures to disconnect devices from the public internet and adhering to security best practices is essential.

By following the guidance provided by Rockwell Automation and leveraging the resources from CISA, organizations can significantly reduce their risk of cyber attacks and protect their critical infrastructure. Remember, cybersecurity is not a one-time effort but an ongoing commitment to vigilance and continuous improvement.

For more detailed guidance and support, customers are encouraged to access the full advisory and related resources provided by Rockwell Automation and CISA. Stay safe, stay secure, and ensure that your industrial control systems are well-protected against the growing cyber threats.

What You Need to Know About Industrial Automation - Explore the essentials of industrial automation, from types and tools to the role of PLCs. Gain insights to modernize your operations.

![]() At InCentrik, we believe in the transformative power of data and digital systems to drive efficiency, innovation, and growth. Our mission is to guide organizations navigating the complexities of an evolving technological landscape by serving as the central hub of knowledge for industrial insights and digital systems. With a strong focus on automation, data management, and process optimization, we specialize in delivering best-in-class technical services and cutting-edge packaged solutions that meet the unique needs of our clients.

At InCentrik, we believe in the transformative power of data and digital systems to drive efficiency, innovation, and growth. Our mission is to guide organizations navigating the complexities of an evolving technological landscape by serving as the central hub of knowledge for industrial insights and digital systems. With a strong focus on automation, data management, and process optimization, we specialize in delivering best-in-class technical services and cutting-edge packaged solutions that meet the unique needs of our clients.

In today's competitive landscape, businesses need to find ways to operate more efficiently and effectively in order to stay ahead of the curve. By...

Navigating the intricate landscape of industrial automation can be a daunting task, yet it's crucial for staying competitive in today's rapidly...

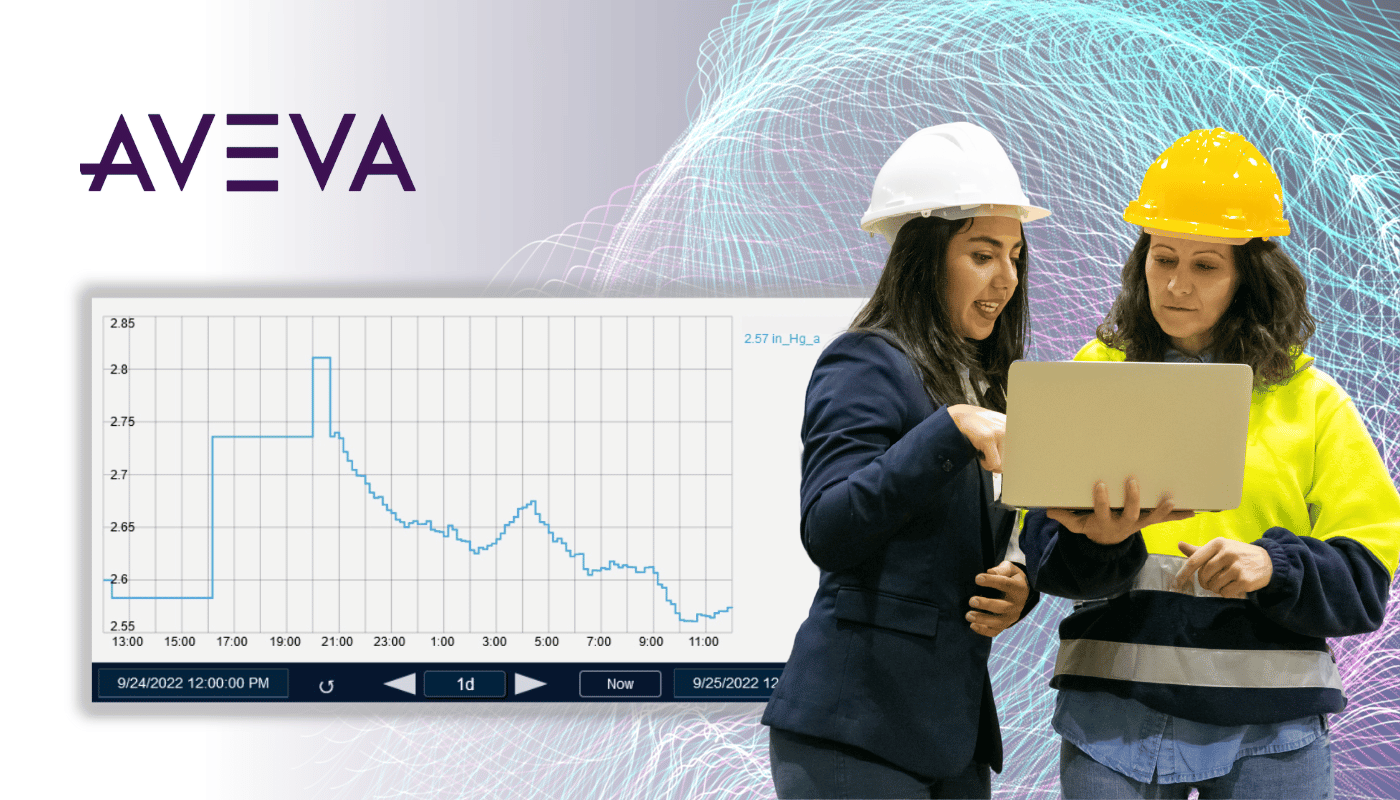

In the realm of industrial automation and data management, AVEVA's PI System (formerly OSIsoft's PI System) stands out as a pivotal technology. As...