Challenge

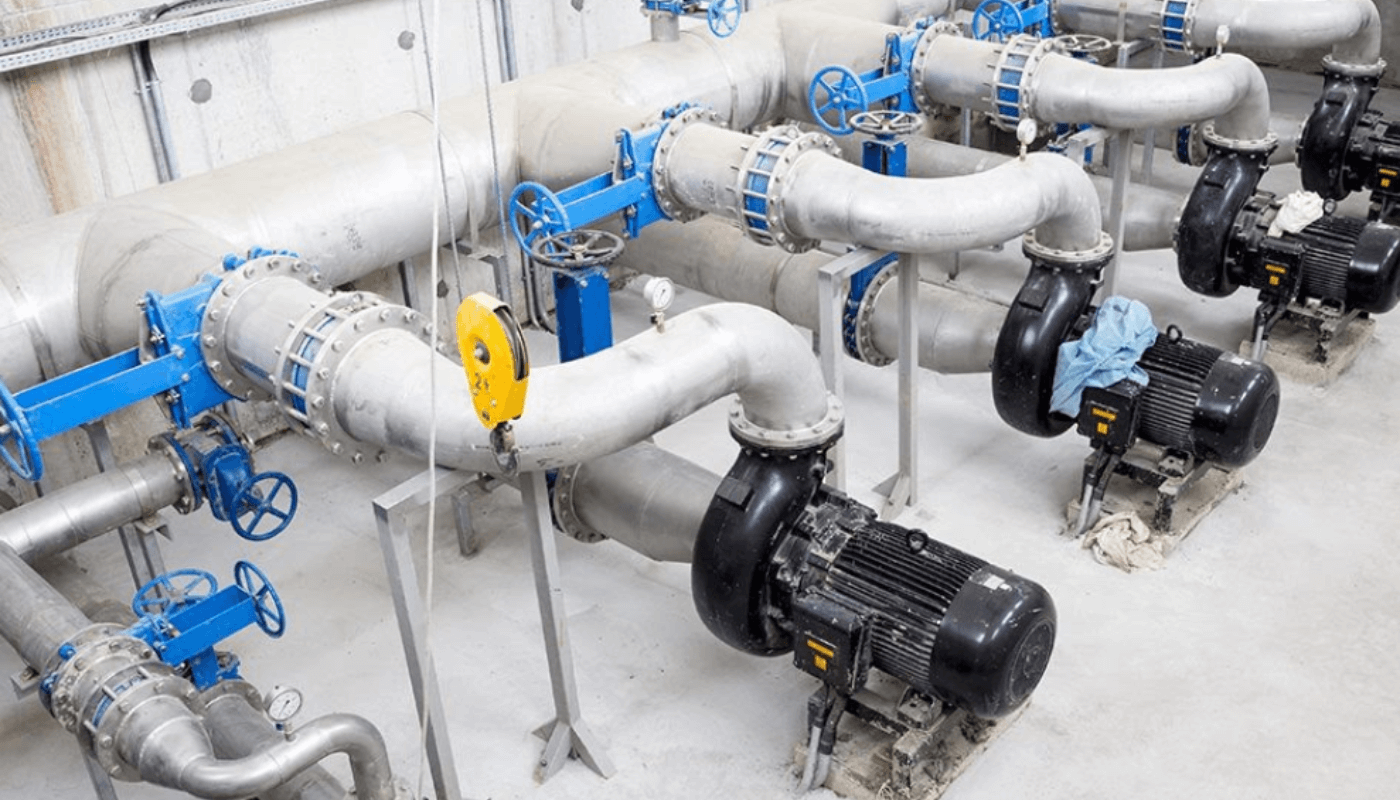

Difficult to characterize pump performance to anticipate pump health in near real-time. Scheduled maintenance can lead to unnecessary work while neglecting maintenance tasks leads to unplanned downtime. This leads to lost revenue and environmental and safety threats.

Solution

Implement a condition-based monitoring analysis to monitor pump health across hundreds of pump assets. Utilize the historical data to create a predictive maintenance forecast to preemptively detect pump failures before they occur.

The state of overall pump health is created by monitoring the pump performance with various analytics which leads to: identifying bad actors, risk identification, and prioritization of maintenance activities.

Results

Enables proactive engineering assessments

Helps to identify risks and prioritize maintenance activities

Reduces likelihood of pump failure, saving costs due to lost production and engineer time.

Details

Read more about this case study from one partners Seeq.

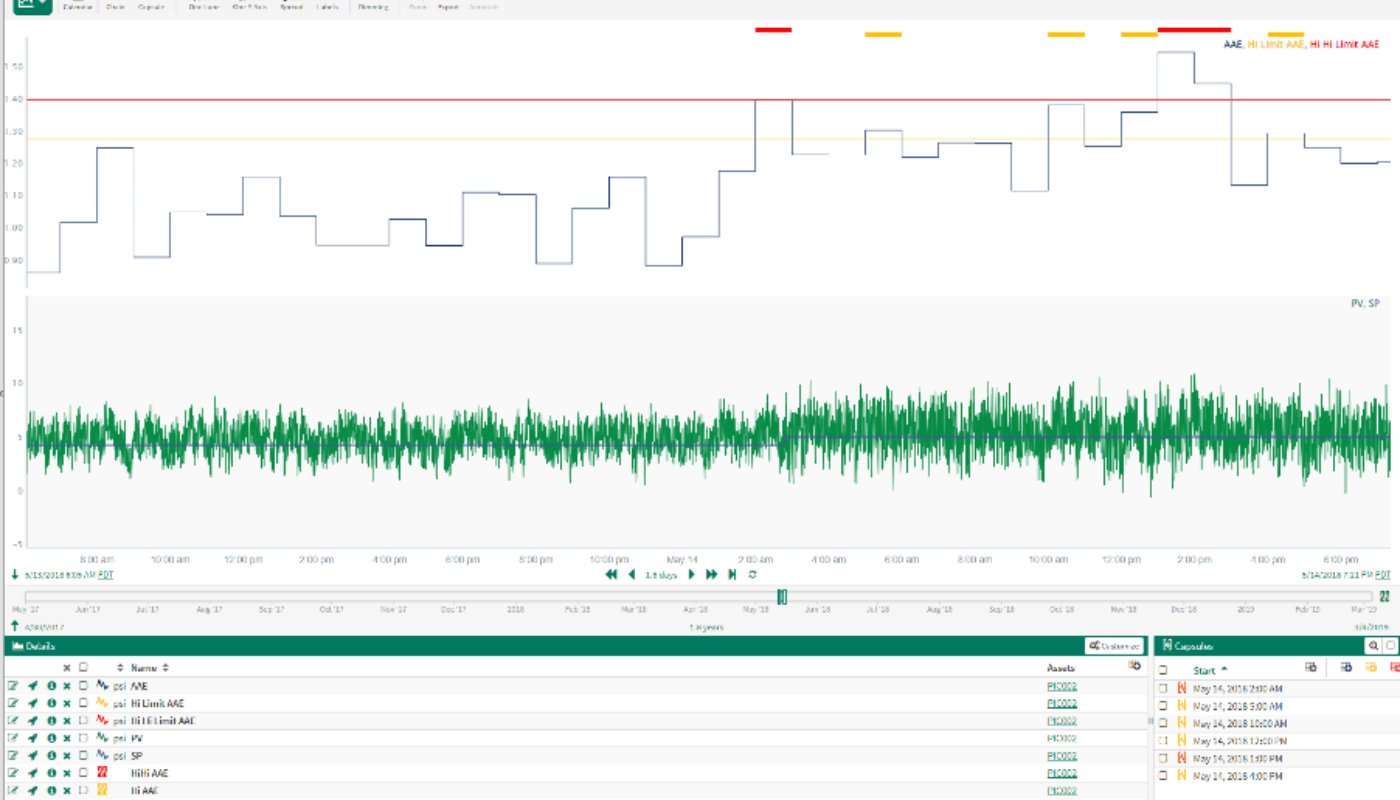

The screenshots show the daily health score for the oil and gas company’s pump and a detailed view showing the leading indicators, which could contribute to poor performance.

InCentrik's Partnership with SEEQ

InCentrik's partnerships with Seeq allow us to provide our clients with advanced analytics solutions that are critical to their operations.

InCentrik's partnerships with Seeq allow us to provide our clients with advanced analytics solutions that are critical to their operations.

Through the partnerships, we can harness diagnostic and predictive analytics to enable greater operational efficiency and deeper insight.

Revolutionizing Alarm Management with Dimension Software

Background InCentrik, a leading technology solutions provider, has partnered with Dimension Software to deliver advanced Alarm Management...